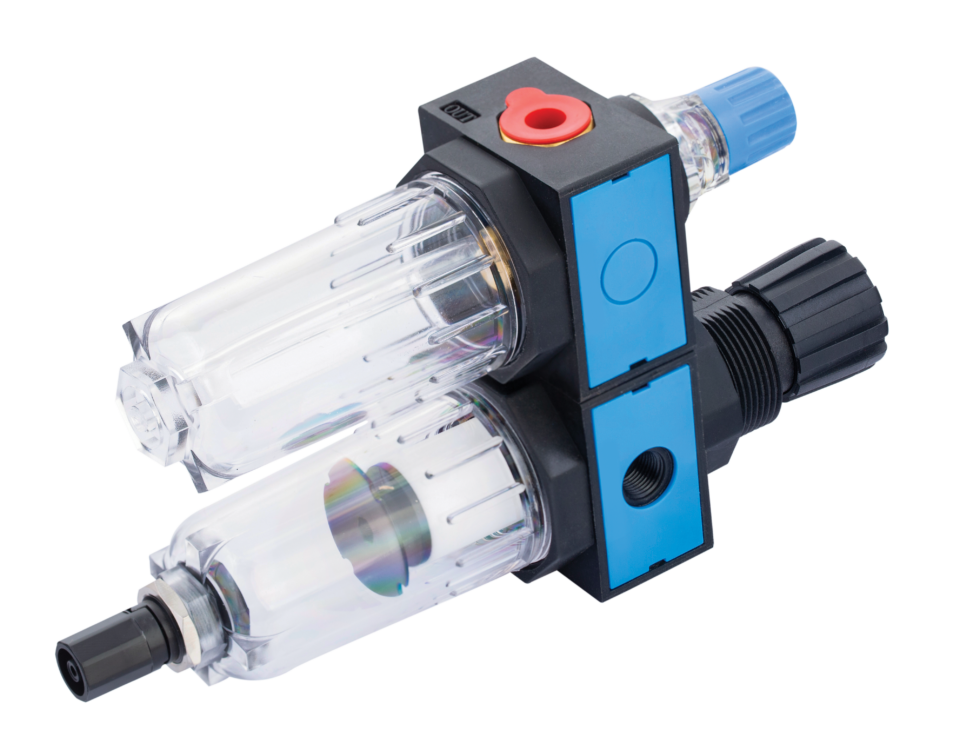

Pneumatic Regulator Air unite

Air treatment units are used for treating air source from air compressor. It includes three parts with different function air filter for filtering the dirt and particles from air source regulator for regulating the pressure of air source; lubricator for oil lubrication

Air Filter Regulator Unit

An Air Filter Regulator Unit is used to treat the air in compressed air systems. Treating air is necessary because air supplied by compressors is tainted with dirt, oil, or water, at the incorrect pressure, and unlubricated for your pneumatic tools or equipment. If treated unproperly, it can be harmful to equipment and reduces their lifespan, and decrease performance. Proper selection of air treatment units on the other hand will ensure smooth performing equipment with increased reliability and life span.

A regulator is used to control the speed and precision of the flow of liquids and air, whereas the filter cleans the air that travels from the compressor. What happens is the airline filter scrubs, strains, and traps solid particles (dust, dirt, rust), and separates liquids (water, oil) within the compressed air.

Filters are installed in the airline upstream of regulators, lubricators, directional control valves, and air-driven devices such as cylinders and air motors.

- Date

- October 24, 2020

Air treatment units are used for treating air source from air compressor. It includes three parts with different function air filter for filtering the dirt and […]- Date

- August 14, 2016

Air source treatment components refer to the various components or devices used in the treatment and purification of air. These components are necessary to maintain indoor […]